Resources and Technology

DESIGN

2D-3D CAD Product Design

Mold and Tooling Design

MANUFACTURING

Tool/Mold Manufacturing

Metal Manufacturing

Injection/Bi-Injection Molding

Injection Blow Molding

DECORATION

Hot Stamping

Heat Transfer Foil

Silk-Screen Printing

SECONDARY PROCESS

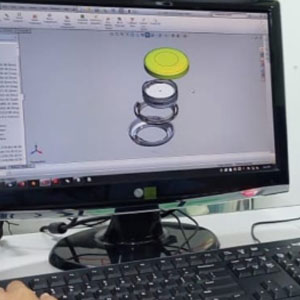

Vacuum Metalizing

UV Coating

Extruder

- In-house extrusion

- In-house color matching

- Master batch preparation

Tooling / Mold Production

Health and beauty industries relies on precision molding to produce HIGH QUALITY PRODUCTS. The result of the finished product depends highly on MOLD DESIGN, STEEL QUALITY, and MOLD MAKING TECHNIQUES.

KEMAS have built its reputation to build high quality mold that can sustain high volume of mass production even surpassing 3 x of its guaranteed shots.

Our technology and innovation gives assurance to our customers that their products will always consistently be manufactured in the highest specification within the industry.

Packaging and Tool Design

- Inhouse Product and Mold Design with engineering support from Japan, Canada, America, Taiwan, China, and Indonesia

- 2D/3D design

- 3D printing support

- Tool Flow Analysis Capability

- Expertise in Mechanism and Innovation Packaging

INJECTION MOLDING

BI-INJECTION MOLDING

INJECTION BLOW MOLDING

- Over 40 years manufacturing experience

- Precision molding expert

- Controlled CLEAN ROOM 100K level

- GMP standard

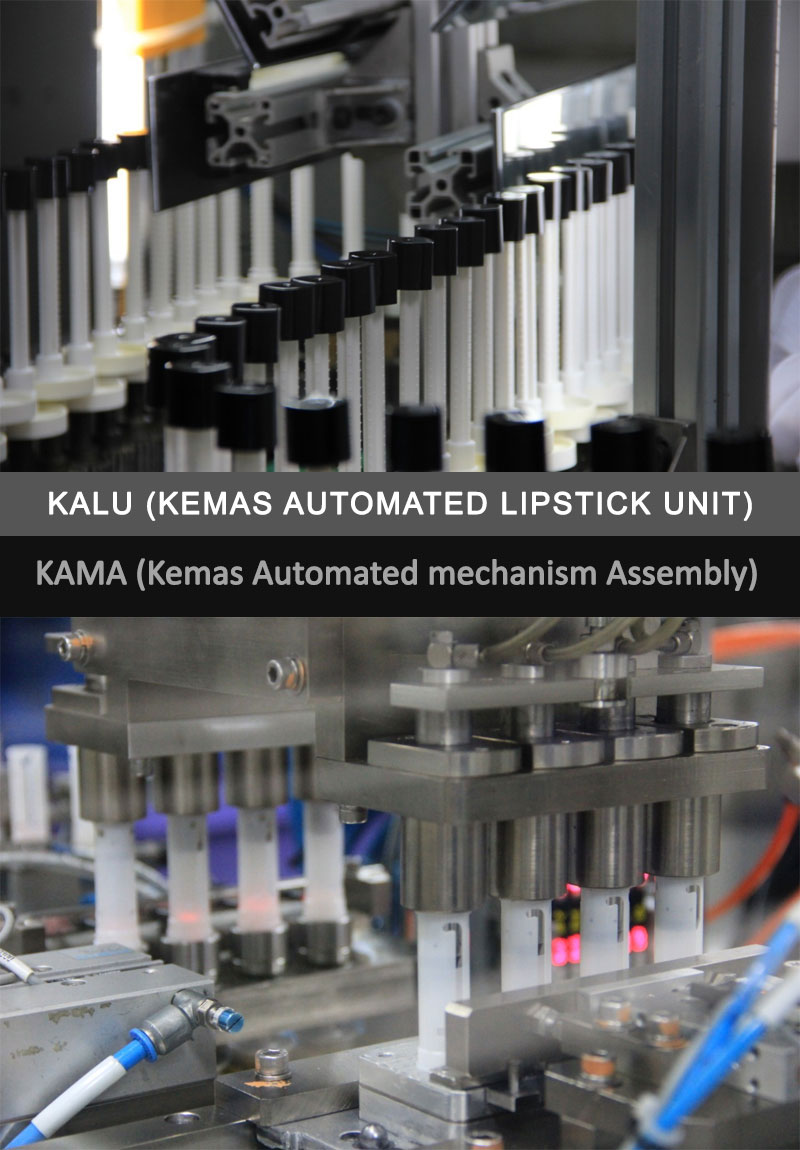

IN HOUSE AUTOMATION ENGINEERING INNOVATION

- KALU – Kemas Automate Lipstick Unit

- KAMA – Kemas Automate Mechanism Assembly

*) We produce almost 200 millions lipsticks category alone per year from International Brands and Domestic Brands

DECORATION

Hot Stamping

Heat Transfer Foil

Hot Stamping technology is the most reliable method as it has the power to adapt to any surface as well as producing color consistency. Moreover, the coat can be varnished on any material to give it a matte, glossy or semi-matte look.

Hot Foil Stamping technology can be integrated with the pad printing and screen printing to make eye catching cosmetic bottles and cosmetic containers. This technology helps the cosmetic industries to print bran related information with enhanced effects and colors.

- Carbon mask for all the operator to ensure safety first

- Debris and Air Contamination controlled room

DECORATION

Silk-Screen Printing and

Laser Printing

- Pad Printing

- 3D Ink Printing

- Laser Printing

Asembling

Two (2) type of Asembling Area :

-

- Dedicated Asembling Area with 100% QC check (Manual and Semi Automated Line)

- Offer 10K Level Asembling Area Options. Medical Category, Japanese High End Brands, High End Brands.

Coating Facilities

- VACCUUM METALLIZING

- UV COATING MATT/GLOSSY

- UV PEARL

- UV METALLIC

Decoration Options

- Dew Drop Effect

- Spiderweb

- Crackle

- Frozen

- Glitter

- Gradation

- Leather Effect

- And many more

KEMAS

METAL PLANT

Joint venture with a Taiwanese SCL for Metal Production Factory in Indonesia, China, and Taiwan in 2019 to produce Aluminum Lipstic, Perfume Caps, Skincare Caps, Mascara Caps, and Aluminum Accessories, etc

Technology

- PIR (Post Industrial Recycled)

- Anodization

- Double Anodization

- Triple Anodization (KEMAS Pioneer the technology)

Metal Plant Production Process

Workshop

Stamping

Polishing

Anodizing

Quality Control

FILLING +

FORMULATORS PARTNERS

By combining our Plastic Factory and Metal Factory as well as partnering with formulator companies in Japan, Italy, Korea, and USA, we are set to be the leading Global Full Turnkey solution for Beauty Brands.

PT. Kemas Indah Maju

Center of Excellence for Global Beauty Packaging Company with Design Innovation Capability, High End Manufacturing Facilities', and OEM collaboration for Cosmetic Brands to complete its Brand Story.

Contact Us

Jl. Rawaterate II No.16

Kawasan Industri Pulo Gadung

Jakarta Timur, Jakarta 13930

Indonesia

+62-21-4608847

+62-21-4608848

+62-21-4608845 (fax)